Precision and everything from a single source

Tailor-made solutions for your projects

At Beichler & Grünenwald, you receive PTFE and plastic components that are precisely tailored to your requirements – from prototypes to series production.

Thanks to our integrated production chain, from our own semi-finished product manufacturing and CNC machining to final assembly, you benefit from short delivery times, minimal interfaces and ready-to-install components.

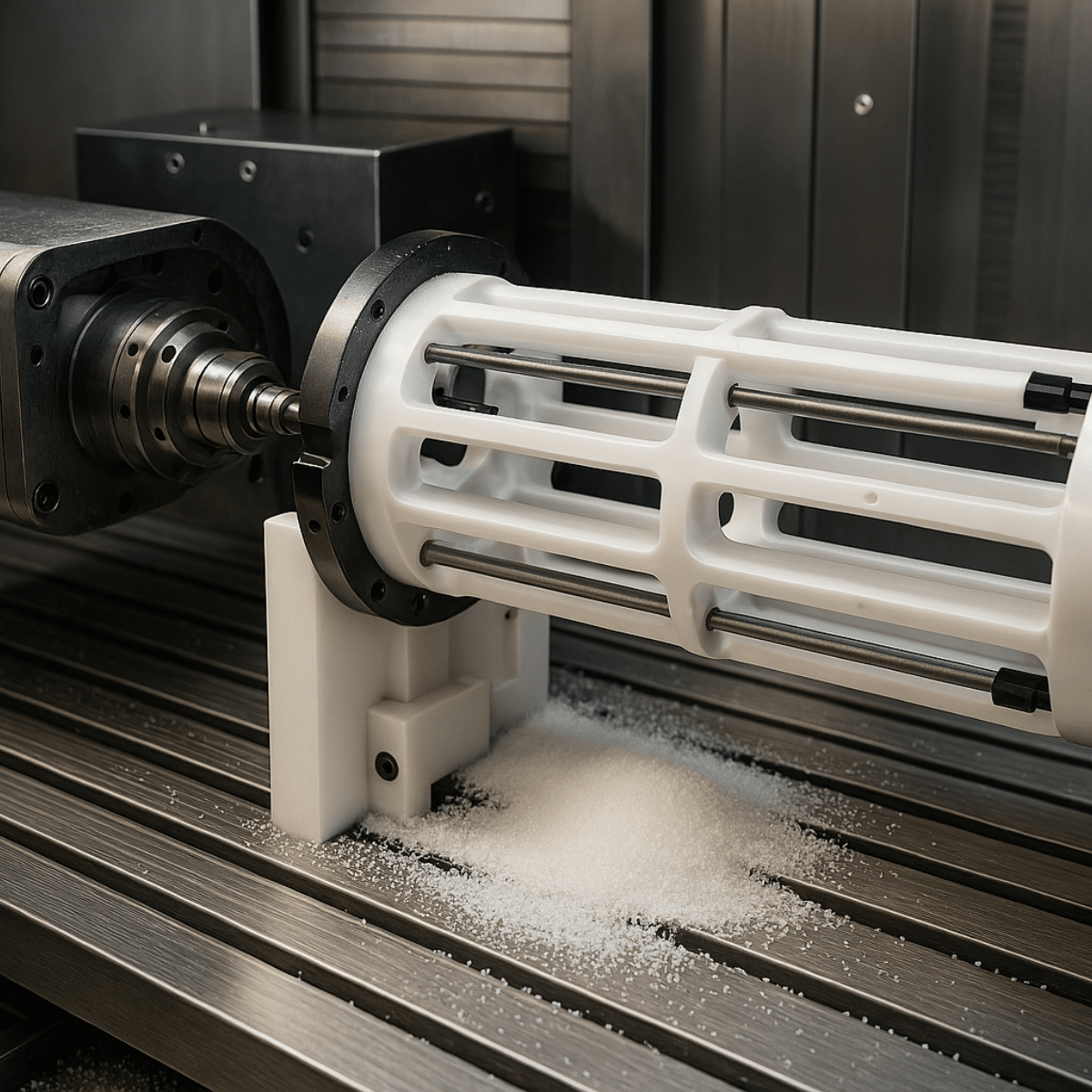

Special CNC parts made of PTFE – fast, precise, reliable

We manufacture customised PTFE turned and milled parts according to drawings or samples and, on request, integrate complex assemblies directly ex works. Our processes solve technical challenges reliably and on schedule.

Our strengths at a glance:

- Short delivery times thanks to our own semi-finished product production and CNC finishing

- Everything from a single source: material, machining, surface finishing, assembly

- TFM and modified PTFE, special compounds, equivalent materials to 3M Dyneon®

- Extrusion and milling of long profiles up to 20 m in length

- Isostatic moulded parts and pressed blanks in special lengths

- Prototypes and series with reproducible precision

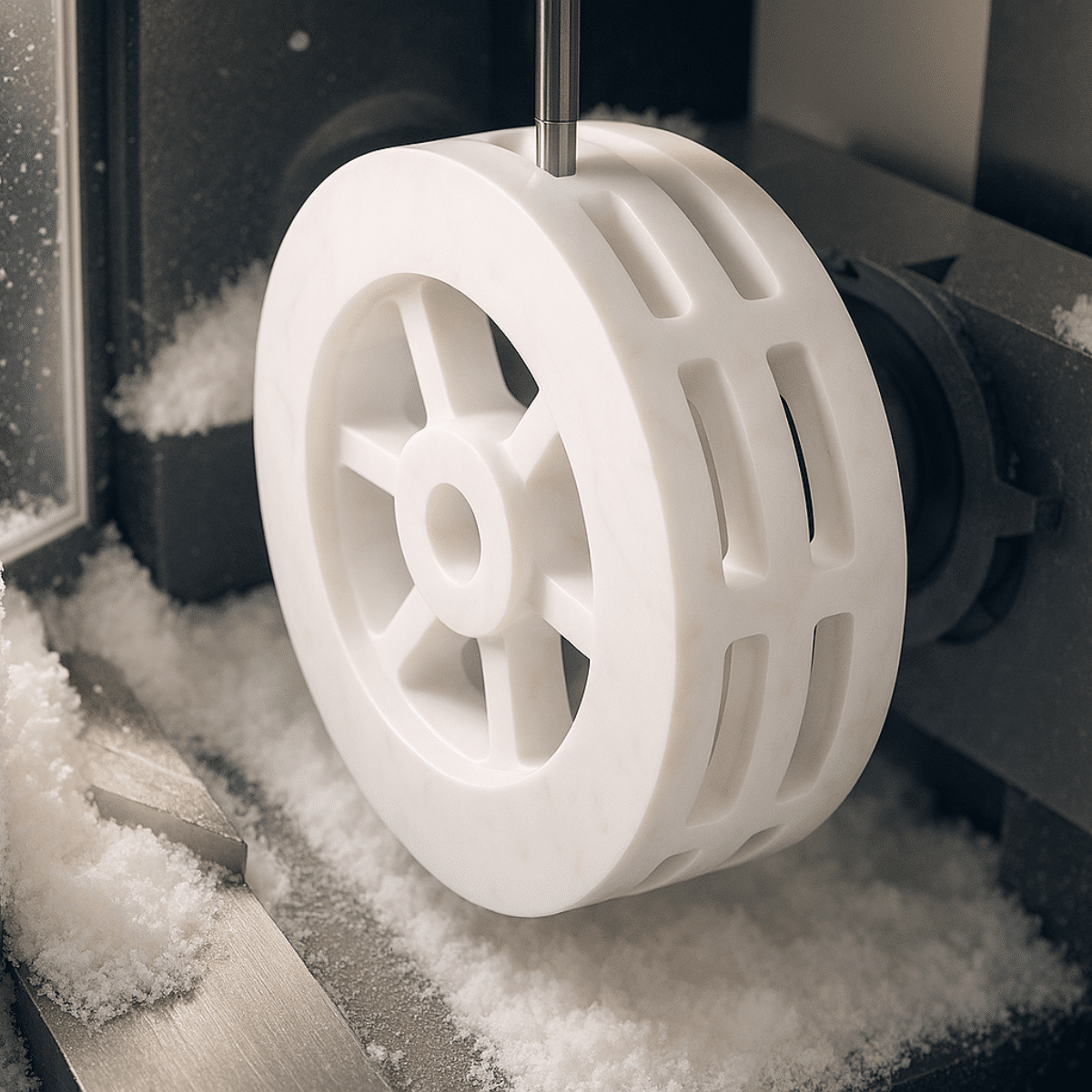

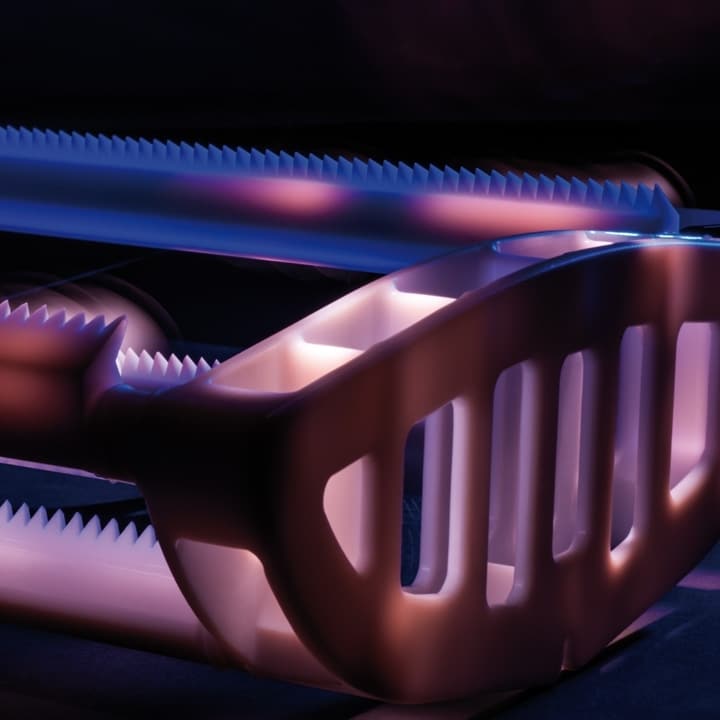

PTFE and plastic milled parts - modern cnc technology for complex geometries

Our CNC milling centres with multi-axis technology machine complex contours and tight tolerances economically and precisely. Individual parts, series or assemblies are manufactured dimensionally accurate and repeatable.

Capacities & manufacturing options:

- Milled parts from 5–1600 mm, slim profiles up to 20 m in length

- Surface finishing: polishing, vibratory grinding, plastic coatings

- Processing of pure/modified PTFE, special compounds and other plastics such as PEEK, PCTFE, PFA and PVDF

- Measuring and testing processes for reproducible quality

What sets our PTFE milled parts apart:

- Precise CNC milled parts according to drawings for complex components

- Cost-effective production of individual parts to series

- Integration of special solutions and assemblies ex works

- Flexible production for PTFE, modified plastics and special compounds

PTFE and plastic turned parts - economical, dimensionally stable and reproducible

With our CNC turning, we manufacture precise round geometries, from prototypes to series production. Thanks to our in-house automatic turning shop and flexible multi-axis technology, turned parts from Ø 0.5–1200 mm are possible.

Key features:

- Turned parts from Ø 0.5–1200 mm

- Processing of semi-finished products from our own production as well as blanks, round rods or profiles provided by the customer

- Finishing: polishing, grinding, coating

- Direct integration of special solutions and assemblies

What sets our PTFE turned parts apart:

- Precise CNC turned parts according to drawings

- Cost-effective production of individual parts and series

- Everything from a single source – material, processing, assembly

- Flexible production for PTFE, modified plastics and special compounds

Our manufacturing chain and services - from raw parts to ready-to-install assemblies

- RAM extrusion of our own semi-finished products

- Isostatic and static pressing of PTFE blanks

- CNC turning and milling

- Surface finishing and final assembly

- Thermal forming, welded joints, laser marking, ultrasonic cleaning

Quality assurance - documented precision precision at every step

Every step of the manufacturing process is monitored: feasibility tests, documented process controls, dimensional checks, dual control principle. The result: reproducible, precise PTFE components and assemblies for demanding applications.

Frequently asked questions about PTFE Components

Precise CNC machining, high dimensional accuracy, process reliability, reproducible quality, single-part and series production.

Pure PTFE, modified variants, special compounds – chemically resistant, insulating, temperature-resistant.

Yes – round bars, profiles, plates or customer-specific blanks.

Thermal forming, welded joints, laser marking, ultrasonic cleaning.

Documented tests, process controls, dimensional testing and the dual control principle.